Siemens CoE (Smart Manufacturing)

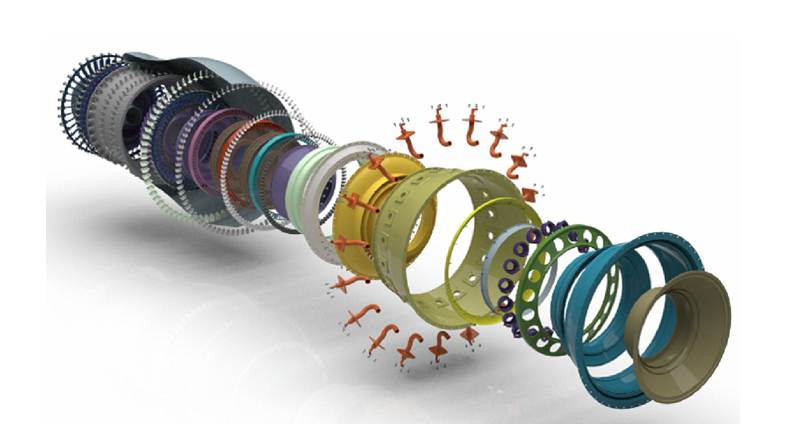

Set up with the collaboration of Siemens Industry Software (India) Private Ltd. (SISW), a strategic business unit of Siemens AG, Germany, this CoE on Smart Manufacturing has eight Labs - Design & Validation (Siemens NX CAD software); Advanced Manufacturing (Teamcenter and Technomatix software); Test & Optimisation Simcenter; STAR – CCM and NX – Nastran software; Process Instrumentation Simatic – PCS 7 software; IoT (Mindsphere software and Mendix Platform); CNC Controller (Sinumeric 808D & 840D milling and turning controllers); CNC Machining (Turning center and 3- axis vertical milling machine) and Robotics (Pick & Place cell and MIG welding cell). The CoE, capable of training students/professionals on entire product lifecycle management (PLM) has the potential to cater to the evolving needs of manufacturing industry as well.

Vision & Mission

VISION

With a focus on design, validation, automation and digitalization, Siemens stands for engineering excellence, innovation, and reliability

MISSION

Our mission is to provide top quality education and training for our students that will enable them to become outstanding and exemplary members of the global workforce

Objective

- To equip students with professional and practical skills, knowledge and experiences that will allow them to thrive and excel at their chosen careers.

- To adhere to students with the learning required to implement Industry 4.0.

- To enable learners with practical skills that will help them better understand the engineering principles and theory.

- To empower students and help them make the most of academic and career opportunities.

- To provide them with positive learning and life experiences through community and work connections.

- To provide local and international students with relevant and innovative educational and training services.

- To give an add-on with functional skills required for overall personality development and corporate performance.

Outcomes

- Students will be able to work on Siemens related technologies with confidence in practical manner.

- To provide students with exposure towards society and need of technology in shaping it further.

- Students will be enabled on Industry 4.0 skills and knowledge.

- Students will be industry ready with hands-on experience in advanced welding equipment.

Facilities

Salient Features

- Server as a Technical Knowledge Resource for industry

- Equipped with State-of-the-Art Tools and Technologies

- Hub for “Technical” Skill Development programs in State in coordination with Universities and Industry Catalyze Industry – Academic Partnership

- Catalyze Industry – Academic Partnership